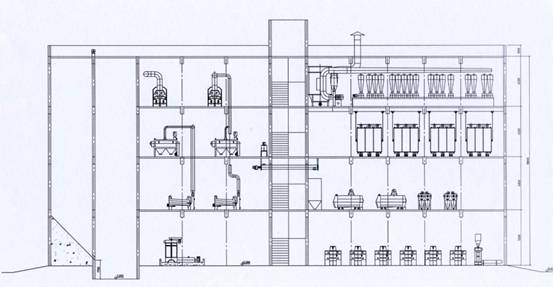

Ground-level Wheat Flour Mills

We have a 100-500 ton per day (t/d) series of complete wheat flour plants designed to operate at ground level. It utilizes a square-plane sifter and newly developed pneumatic roller mill. The mills were designed by KMEC's engineers after undertaking a thorough analysis of flour mill processes from all over China. The resulting compact, low cost, simple, quickly assembled machinery produces high yields and is the first choice of medium and large flour milling processing plants.

This series includes the 100, 120, 140, 160, 180, 200, 300, 350, and 500 t/d models.

|

Grades |

Power (kW) |

Power consumption per ton of flour (kWh) |

Capacity (t/d) |

Workshop dimensions (L*W*H)(m) |

|

Grade 1 flour, Grade 2 flour, Special flour |

600 |

60-70 |

200 |

60*7.5*23 |

300 t/d Ground-level Flour Milling Process

Technical specifications of the flour milling process: 4B, 8M, 2S, 2T, 2BrF, 1BrB, 5P, 3B, 4B, 1M, and 2M, the last of which has a different reduction and smooth roll flour production process.

Technical specifications for wheat cleaning: 1 pre-cleaning unit, 3 sieves, 2 scourers, 2 stoners, 1 foreign seed extractor, 3 magnetic separation units and 1 dampener.

|

Grades |

Power (kW) |

Power consumption per ton of flour (kWh) |

Capacity (t/d) |

Workshop dimensions(L*W*H)(m) |

|

Grade1 flour, Grade2 flour, Special flour |

1,000 |

60-70 |

300 |

60*7.5*23 |

Besides ground-level only operation, these processes can be stacked over two or more stories (see also our Elevated Flour Mills section).

|

Model |

Workshop size |

Main equipment and milling process |

Power (kW) |

Flour yield(%) |

|

250 TPD Wheat Flour Plant |

48×16.2×27.6 |

Cleaning workshop: 100×200 sieve, 100×150 roto-sifter, 45×100 wheat scourer, 40 wheat brushers, 100 cyclone sieves, 125 gravity stoners, 150 sucking stoners, foreign seed extractor, 15 intensive dampeners, auto-atomizing dampener, and a duster and elevator combined cleaning process. |

730 |

Grade one |

|

300 TPD Wheat Flour Plant |

48×16.2×27.6 |

Cleaning workshop: 150×200 sieve, 125×150 plane rotation sieve, 45×100 wheat scourer, 45×100 wheat scourer, 40 wheat brushes, 100 cyclone sieves, 125 gravity stoners, 150 sucking stoners, foreign seed extractor, 15 intensive dampeners, auto-atomizing dampener, and a duster and elevator combined cleaning process. |

886 |

Grade one |